Call Us

+86-22-2764-6507

| Availability: | |

|---|---|

Description

The KLD200 3-way high pressure motorized ball valve (stainless steel, 1/4" to 3/4") is designed for high pressure applications, capable of withstanding high working pressures up to PN315, suitable for high pressure situations. It features a compact structure, easy operation, and precise control, making it ideal for water treatment systems, cleaning systems, small equipment automation, industrial automation, and hydraulic systems, enabling remote and automated control of the medium.

Technical specifications include

Valve type: 3-way high pressure electric ball valve

Diameter: DN8, DN10, DN15, DN20

Connection type: Threaded

Pressure: Maximum 31.5MPa (PN315)

Flow: Varies with valve size and application

Medium temperature: 0°C to 100°C

Ambient temperature: -15°C to 45°C

The KLD200 3-way high pressure motorized ball valve (stainless steel, 1/4" to 3/4") offers a compact size, long service life, stable driving performance, and optional safety features. It is widely used in various control systems and is an ideal choice for achieving automation control.

CE approved

Applications

Water treatment system

Washing system

Small equipment for automatic control

Industrial automation

Hydraulic system

Technical Data

Rated Torque | Nominal Voltage | Power | Wiring | Running Time | ProtectionClass | Max Pressure | Medium Temp. |

20NM | DC24V | 85W | B3S/BD3S | 1S | IP67 or F Type | 31.50Mpa | 0-100℃ ※ |

15NM | DC12V | 15W / 25W@KT | B2S/B3S/BD3S/KT32S | 15S | |||

20NM | DC12Vh | 25W@10S 36W@KT | 10S | ||||

20NM 15Nm@6S | AC/DC24V | 15W@10S/25W@6S/36@KT | 10S/6S | ||||

AC/DC95-265V | 15W@10S/25W@6S/36@KT | B3S/BD3S/KT32S | |||||

20NM | AC24V | 15W | B3S/BD3S | 15S | |||

AC110V | |||||||

AC220V |

※ It needs to add high-temperature bracket if medium temperature is over 100 ℃.

Main Components Diagram

Main Components

| No. | Components | Material | Qty |

| 1 | Body | 304/316L | 1 |

| 2 | Ball | 304/316L | 1 |

| 3 | Ball seat | PTFE | 1 |

| 4 | Cable connector | Nylon, nickel-plated brass | 1 |

| 5 | Housing | PC alloy※/ die-casting aluminum | 1 |

| 6 | Label | PC | 1 |

| 7 | Indication window | Transparent PC | 1 |

| 8 | Hexagonal wrench | Tool steel | 1 |

※Avoid direct or indirect contact between PC and organic solvents such as toluene, xylene, ketones, dichloromethane, trichloromethane, and chloroform ect., due to corrosion resistance characteristics of PC materials.

Dimensions【DN8-DN20】

Dimensions(mm)

DN | G1 | L1=L2=L3 | L | L4 | d | F | H1 | H2 | H | W(Kg) |

DN8 | G1/4″ | 12 | 77 | 57 | 7 | 27 | 28 | 40 | 151 | - |

DN10 | G3/8″ | 12 | 77 | 57 | 7 | 27 | 28 | 40 | 151 | - |

DN15 | G1/2″ | 12 | 83 | 62.5 | 12 | 36 | 33 | 44.5 | 160.5 | - |

DN20 | G3/4″ | 15 | 93 | 67.5 | 12 | 36 | 33 | 44.5 | 160.5 | - |

Notes:BSP,NPT,GB ect. is optional.

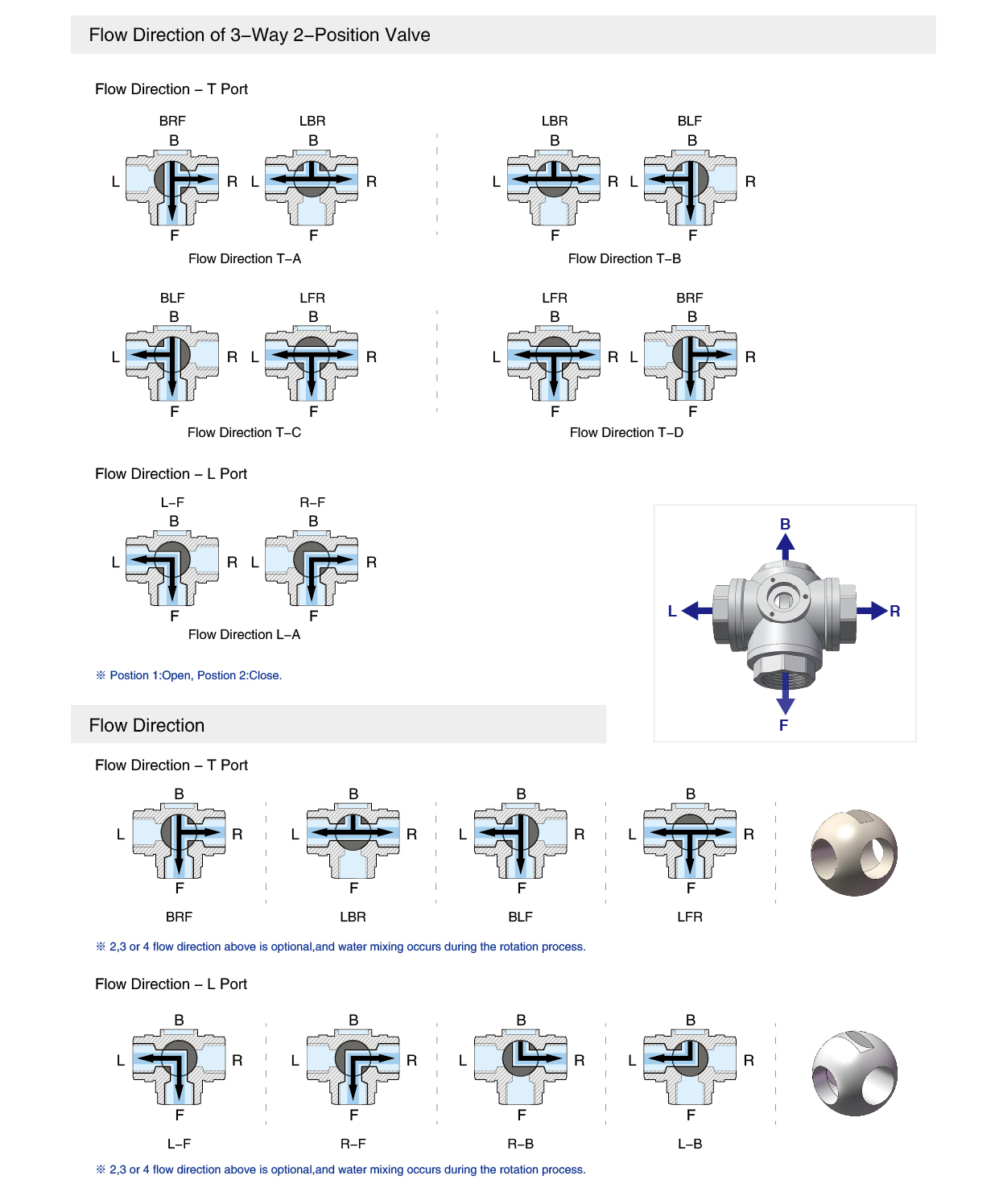

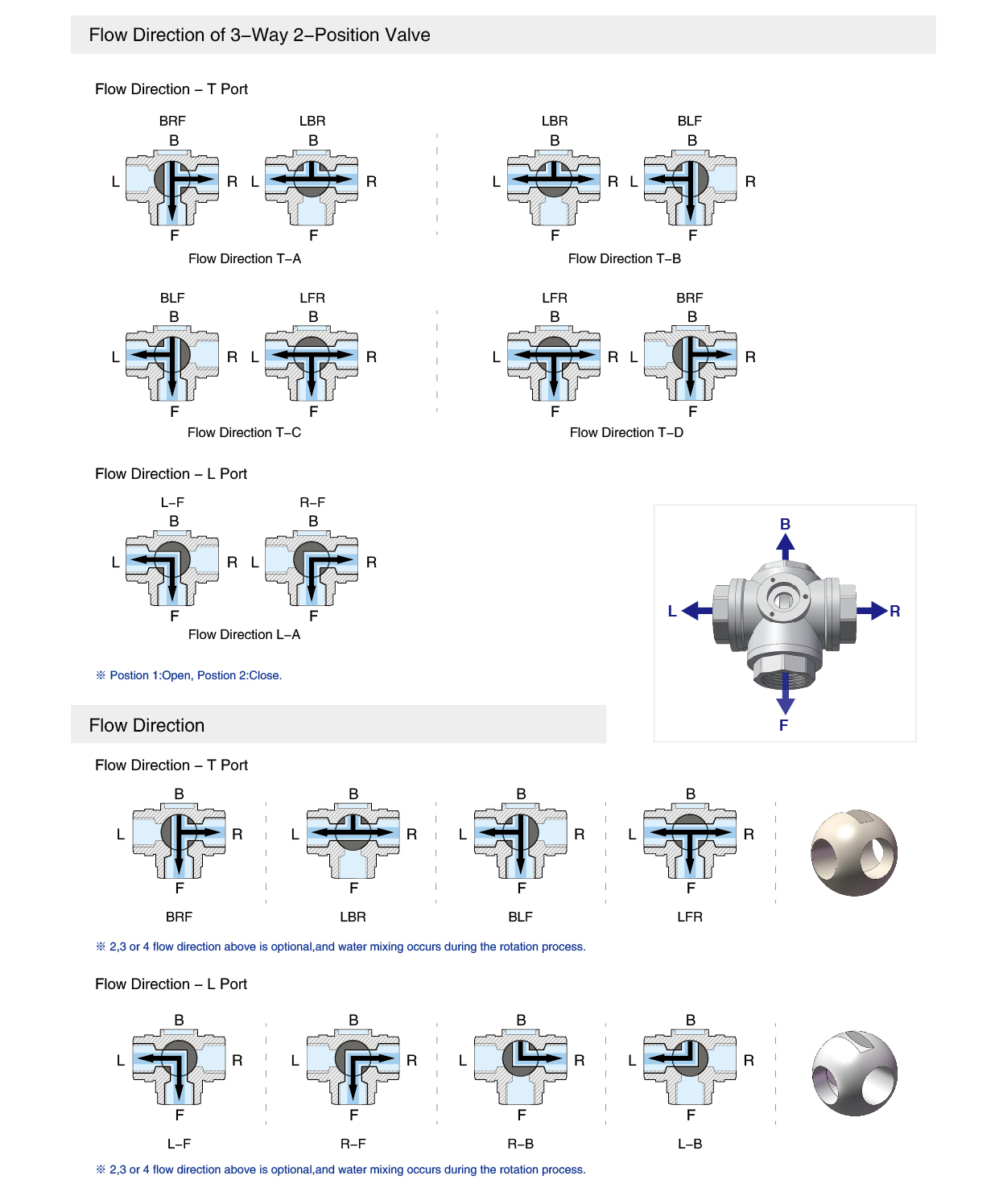

Flow Direction

Functional Data

Angle of Rotation | 90°±2° |

Degree of Protection | IP67 As Per En60529/GB4208-2008(alldirections) F type [damp-proof,adding dehumidifying heater] |

Manual Override | Matching hexagon wrench(only using at no power) |

| Position Indicator |  |

Working Conditions

Ambient Temp. | -15℃<t<45℃(can be customized for other temp.) |

Ambient Humidity | 5-95%RH,non-condensing |

| Medium Temp. | 0—100℃ |

※Subject to technical changes

Description

The KLD200 3-way high pressure motorized ball valve (stainless steel, 1/4" to 3/4") is designed for high pressure applications, capable of withstanding high working pressures up to PN315, suitable for high pressure situations. It features a compact structure, easy operation, and precise control, making it ideal for water treatment systems, cleaning systems, small equipment automation, industrial automation, and hydraulic systems, enabling remote and automated control of the medium.

Technical specifications include

Valve type: 3-way high pressure electric ball valve

Diameter: DN8, DN10, DN15, DN20

Connection type: Threaded

Pressure: Maximum 31.5MPa (PN315)

Flow: Varies with valve size and application

Medium temperature: 0°C to 100°C

Ambient temperature: -15°C to 45°C

The KLD200 3-way high pressure motorized ball valve (stainless steel, 1/4" to 3/4") offers a compact size, long service life, stable driving performance, and optional safety features. It is widely used in various control systems and is an ideal choice for achieving automation control.

CE approved

Applications

Water treatment system

Washing system

Small equipment for automatic control

Industrial automation

Hydraulic system

Technical Data

Rated Torque | Nominal Voltage | Power | Wiring | Running Time | ProtectionClass | Max Pressure | Medium Temp. |

20NM | DC24V | 85W | B3S/BD3S | 1S | IP67 or F Type | 31.50Mpa | 0-100℃ ※ |

15NM | DC12V | 15W / 25W@KT | B2S/B3S/BD3S/KT32S | 15S | |||

20NM | DC12Vh | 25W@10S 36W@KT | 10S | ||||

20NM 15Nm@6S | AC/DC24V | 15W@10S/25W@6S/36@KT | 10S/6S | ||||

AC/DC95-265V | 15W@10S/25W@6S/36@KT | B3S/BD3S/KT32S | |||||

20NM | AC24V | 15W | B3S/BD3S | 15S | |||

AC110V | |||||||

AC220V |

※ It needs to add high-temperature bracket if medium temperature is over 100 ℃.

Main Components Diagram

Main Components

| No. | Components | Material | Qty |

| 1 | Body | 304/316L | 1 |

| 2 | Ball | 304/316L | 1 |

| 3 | Ball seat | PTFE | 1 |

| 4 | Cable connector | Nylon, nickel-plated brass | 1 |

| 5 | Housing | PC alloy※/ die-casting aluminum | 1 |

| 6 | Label | PC | 1 |

| 7 | Indication window | Transparent PC | 1 |

| 8 | Hexagonal wrench | Tool steel | 1 |

※Avoid direct or indirect contact between PC and organic solvents such as toluene, xylene, ketones, dichloromethane, trichloromethane, and chloroform ect., due to corrosion resistance characteristics of PC materials.

Dimensions【DN8-DN20】

Dimensions(mm)

DN | G1 | L1=L2=L3 | L | L4 | d | F | H1 | H2 | H | W(Kg) |

DN8 | G1/4″ | 12 | 77 | 57 | 7 | 27 | 28 | 40 | 151 | - |

DN10 | G3/8″ | 12 | 77 | 57 | 7 | 27 | 28 | 40 | 151 | - |

DN15 | G1/2″ | 12 | 83 | 62.5 | 12 | 36 | 33 | 44.5 | 160.5 | - |

DN20 | G3/4″ | 15 | 93 | 67.5 | 12 | 36 | 33 | 44.5 | 160.5 | - |

Notes:BSP,NPT,GB ect. is optional.

Flow Direction

Functional Data

Angle of Rotation | 90°±2° |

Degree of Protection | IP67 As Per En60529/GB4208-2008(alldirections) F type [damp-proof,adding dehumidifying heater] |

Manual Override | Matching hexagon wrench(only using at no power) |

| Position Indicator |  |

Working Conditions

Ambient Temp. | -15℃<t<45℃(can be customized for other temp.) |

Ambient Humidity | 5-95%RH,non-condensing |

| Medium Temp. | 0—100℃ |

※Subject to technical changes